|

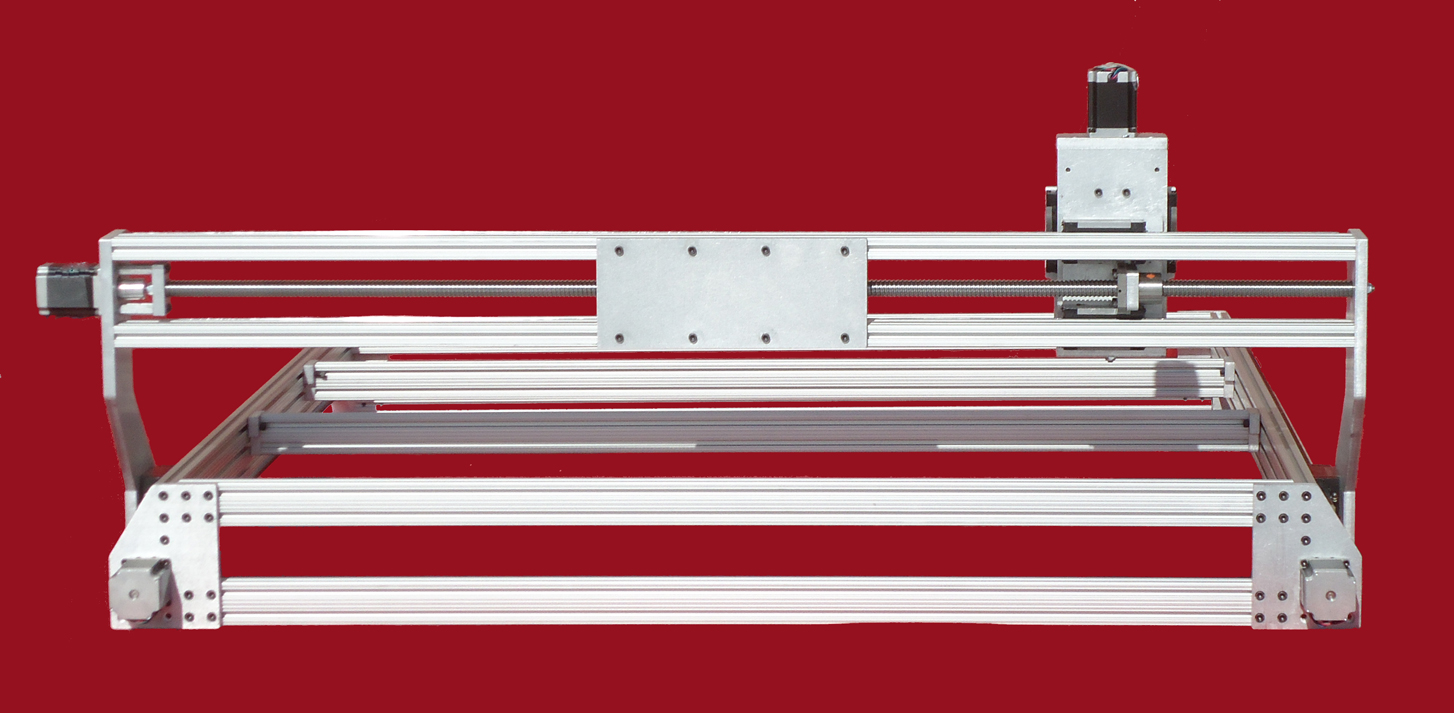

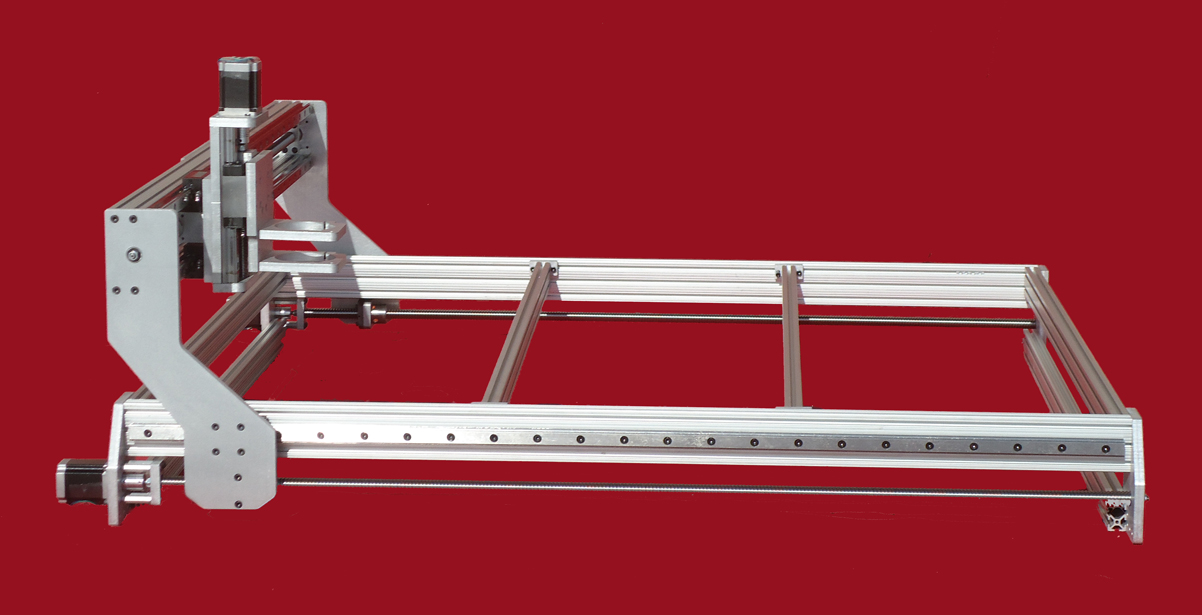

This large platform CNC machine is built for accuracy and precision;

it’s capable of 2D and 3D cutting; and is machined from a

combination of tough unyielding 6061 aluminum and precision aluminum

extrusions.

By placing high tolerance ball screws on either side of the outbound

Y axis, instead of in the center of this larger machine’s work area

prevents it from moving or flexing. The center braces can also be

easily removed so a water table can be installed for plasma cutting.

It’s able to be pushed harder and faster than the round rod linear

bearing types.

|

SPECIFICATIONS: |

| * |

|

Work area 55” x 55” |

| * |

|

Maximum milling area 49.5” x 49.5” |

| * |

|

Z axis (travel and clearance) 4” |

|

|

25 mm rigid rail and carriage bearing ways on X, Y, Z

|

|

|

16 mm C7 anti backlash rolled high tolerance ball screws on

Z axis |

|

|

20 mm C7 anti backlash rolled high tolerance ball screws on

X, Y axis |

| |

|

PROTOTYPE OR

PRODUCTION CUT: |

| * |

|

Carbon Fiber |

| * |

|

Aluminum |

| * |

Plastics |

| * |

Wood |

| * |

Brass |

| * |

Foam (and many more) |

|